What were the first golf balls made of? The first golf balls were made of wood, usually beech or elm, and were carved by hand. Around the 1600s, they changed to featherie balls, leather shells stuffed with boiled goose feathers.

These were tightly sewn and dried to hold their shape. In 1848, gutta-percha balls made from tree sap became popular because they were cheaper and lasted longer.

By 1898, balls with a rubber core were invented, which led to the modern golf balls used today.

This article explores the real materials used in the first golf balls, from hardwood to leather stuffed with feathers.

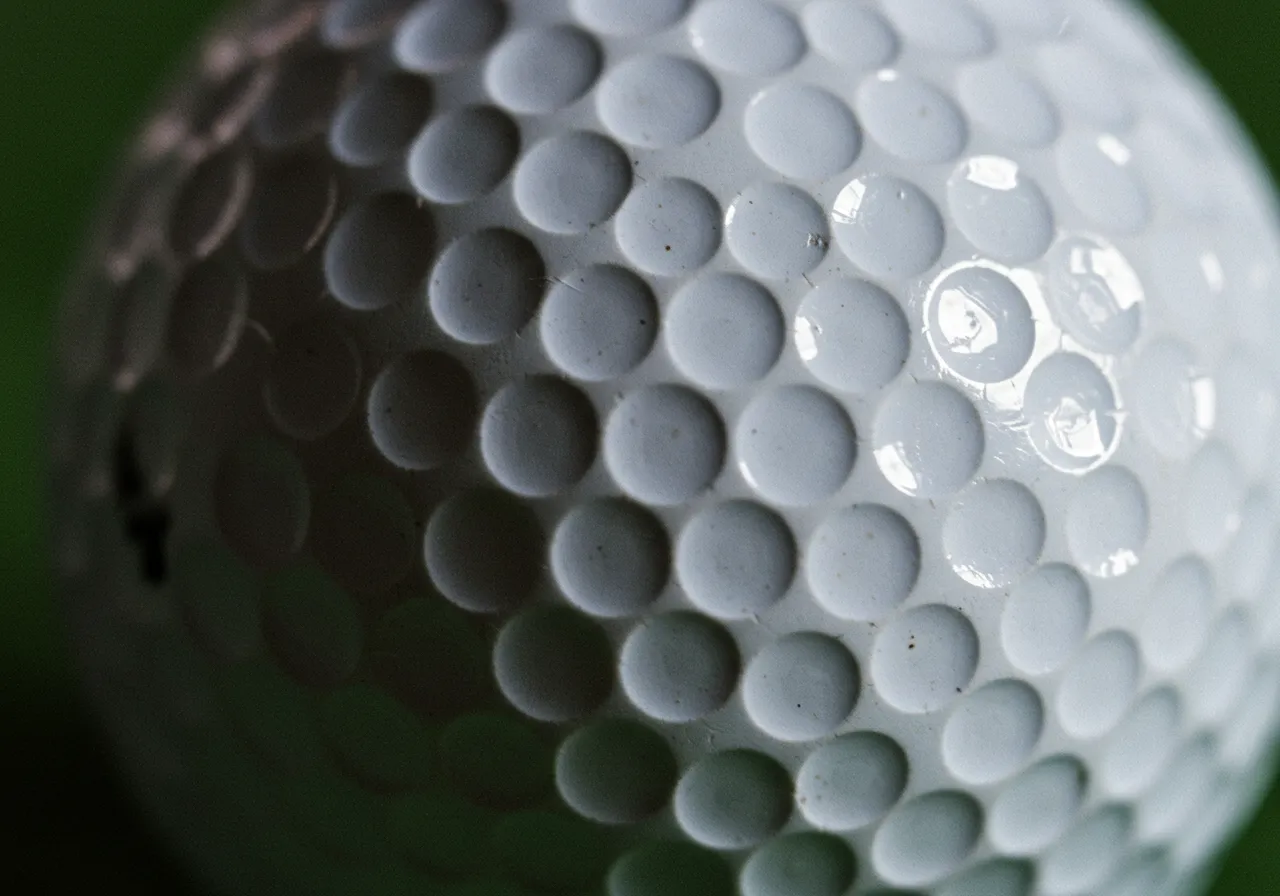

You’ll learn how the little dimples on golf balls and the materials inside help the ball go farther and straighter. You’ll also find out the real facts behind some myths about how old golf balls were made.

What Were the First Golf Balls Made Of in History

When we talk about modern golf balls, with soft urethane covers, dimple designs, and multi-layer cores, it’s easy to forget how far they’ve come.

But as someone who lives and breathes golf, I always like to look back and appreciate how it all started.

What were the first golf balls made of?

The first golf balls ever made were carved out of hardwood, mostly beech or boxwood, way back in the 1400s and 1500s.

These wooden balls were heavy, didn’t fly very far, and were all made by hand. But they helped create the game we love today.

Over time, ball materials changed, and with them, the way golf was played changed too.

As someone who’s trained with both featheries and modern Pro V1s (just for fun), I can tell you: the material of the ball really matters.

It affects distance, feel, spin, and accuracy. That’s why understanding the history of golf ball materials helps us see how the game evolved from a Scottish pastime to a global sport.

Why Knowing the History of Golf Balls Helps You Understand the Game

If you want to understand golf, really understand it, you need to know how the equipment shaped it.

From leather and feathers to tree sap and rubber, each version of the golf ball brought a big change to how far and how accurately people could play.

Some myths even say early balls were made from cow eyeballs.

The True Origins of Golf Balls: Materials and Timeline from a Golfer’s View

When I think about how golf balls used to be made, it blows my mind. We’ve gone from carving wood to hitting multi-layer tour balls. Let me walk you through where it all started.

What Were the First Golf Balls Made Of in the 1400s

In the early days of golf, around the 1400s, the first golf balls were made from hardwood like beech or boxwood.

I once hit a replica during a museum demo; it was solid, heavy, and didn’t fly far at all.

- Size: About 1.5 inches across

- Weight: Very inconsistent from one ball to another

- Distance: Around 100 yards or less

- Shape: The Smooth surface made it hard to control

- Build: Each ball was carved by hand

These wooden balls were basic but helped start the game. They didn’t go far or spin well, but they were part of golf’s foundation.

What Was Inside Old Golf Balls Like the Featherie (1618–1848)

Later came the featherie ball, which was a big improvement. These were made by sewing leather into a round shape and stuffing it with boiled goose feathers.

As the feathers dried, they expanded and made the ball firm and round.

- Materials: Cowhide leather and goose feathers

- Made by hand: Each ball took over 10 hours to finish

- Cost: Would cost about $20 to $50 today

- Distance: Could fly up to 180 yards, which was impressive for the time

- Use: Mostly used by rich or elite players

I’ve tried hitting a featherie replica too, it feels soft and light at first, but doesn’t give the control or spin of a modern ball. Still, it changed the game completely in its time.

What Were Golf Balls Originally Made Of and Why Did They Change

Golf balls started with natural materials like wood, leather, and feathers. But these materials didn’t last long, were hard to make, and were expensive.

That’s why, in the mid-1800s, players moved to new materials like gutta-percha, and later to rubber, which helped shape the modern game.

Comparison Table: The First Golf Balls – Wood vs. Featherie

| Feature | Wooden Ball (1400s–1610s) | Featherie Ball (1618–1848) |

| Material | Beech or boxwood (hardwood) | Cowhide leather filled with goose feathers |

| Construction Method | Hand-carved from a single block | Hand-stitched leather, packed with boiled feathers |

| Diameter | ~1.5 inches | ~1.6–1.7 inches (varied slightly) |

| Weight | Inconsistent (~40–60 grams) | Around 27–30 grams |

| Flight Distance | Up to 100 yards | Up to 180–200 yards |

| Durability | Poor (easily cracked) | Moderate (sensitive to wet weather) |

| Cost (modern value) | Very low | $20–$50 per ball (equivalent today) |

| Production Time | Few minutes | 3–10+ hours per ball |

| Used By | Commoners, early players | Wealthy players and club members |

| Main Limitation | Short range, poor control | High cost, not water-resistant |

| Historic Impact | Origin of golf ball design | Major leap in flight and performance |

Note: This table helps summarize how golf balls evolved from simple wooden shapes to handcrafted featheries that introduced real performance improvements.

Geographic Evolution of Golf Balls: What Were the First Golf Balls Made of in the World and in Early America

What Were the First Golf Balls Made of in the World During the 1400s

The very first golf balls in the world came from Scotland in the 1400s. These early balls were made from hardwood, like beech or boxwood, and were carved by hand.

Later, Scottish makers introduced the featherie, a leather-covered ball stuffed with boiled goose feathers. These balls flew better and were used for over 200 years.

At that time, if you played golf anywhere in the world, Ireland, England, or France, you likely used a Scottish-made featherie.

The craft was so precise that each ball could take 10 hours to finish. But they were also expensive, which kept the game mostly in the hands of the rich.

What Were the First Golf Balls Made of in America During the 1800s

When golf started appearing in America in the early 1800s, there were no U.S.-made balls yet. Golfers in the U.S. imported featherie balls from Scotland and England.

These imported balls were rare and costly, so only a few people could afford to play.

That changed after 1848, when gutta-percha balls were introduced in Britain. Made from dried sap of a Malaysian tree, these balls were cheaper, tougher, and easier to produce than featheries.

Soon, American golfers switched to gutta-percha balls, which made the sport more accessible across the country.

As a pro who’s visited both historic Scottish courses and U.S. clubs, I’ve seen how this switch helped golf grow fast in America.

A simple change in material helped open the game to new players, new places, and a new era.

Debunking Golf Ball Myths: What Were Old Golf Balls Really Made Of

“I’ve heard some strange things, like golf balls being made from cow eyeballs. Let’s clear up the facts with real history.”

Were the First Golf Balls Made from Dried Cow Eyeballs

One popular myth says that early golf balls were made from dried cow eyeballs. I’ve even had young golfers ask me this during lessons.

But here’s the truth: there is no real proof this ever happened.

The confusion likely comes from the featherie ball, which used leather from cowhide to hold the boiled goose feathers inside.

It looked soft and round like an eyeball, but it was just leather and feathers, not animal parts.

As someone who has held an original-style featherie, I can tell you, it feels nothing like an eyeball and everything like tough, stitched leather.

Did Smooth Golf Balls Fly Further Than Dimpled Ones

Another myth is that smooth golf balls flew farther than modern dimpled ones. That’s actually not true.

When the gutta-percha ball was first made in 1848, it had a smooth surface. But players noticed it didn’t fly very far.

Over time, they saw that scuffed or scratched balls went farther. That’s when makers started adding patterns and dimples, which helped the ball cut through the air better.

Today, every golf ball has a dimple pattern because it adds lift, distance, and stability. I’ve hit both smooth and dimpled balls in demos, and trust me, dimples make all the difference.

The Golf Ball Material Revolution: From Tree Sap to Tour Tech

“As someone who’s played both vintage and modern golf balls, I can tell you that what they’re made of makes all the difference. Let’s walk through how golf balls changed over time.”

What is the History of the Gutty Golf Ball Made from Tree Sap

In 1848, the gutty ball was introduced, and it was a total game-changer. It was made from the dried sap of the Palaquium tree found in Malaysia.

When warmed, the sap could be shaped into a ball. Once cooled, it hardened and was ready to hit.

Players started noticing that smooth gutta balls didn’t fly far. But when they got scratched, they flew better.

That led to hand-hammering the surface to add texture, and eventually, the first mass-produced textured golf balls were born.

I’ve hit a gutty replica at a vintage tournament, it’s tough and feels heavy, but it showed how much early golfers learned just by playing.

What Were Golf Balls Made of in 1920

By 1900, the Haskell ball became the new standard. It used a solid rubber core, wrapped with rubber threads, and had a gutta-percha cover.

This ball was lighter, more powerful, and could go farther than any ball before it. By 1920, most golf balls used this rubber-core, wound-layer design.

It was the beginning of modern ball performance, better spin, better control, and longer drives.

When I was younger, I tried an old Haskell ball in a training session; it felt bouncy and fast off the clubface, much closer to today’s balls than the gutty ever was.

What Is the Outside of a Golf Ball Made of Today

Since the 1930s, golf balls have become even more advanced. Today, they are made with synthetic materials like Surlyn or urethane covers, which improve both durability and spin control.

Inside, most tour-level balls have 3 to 5 layers, including a rubber or resin core and special mantle layers for speed, feel, and accuracy.

Personally, I use a urethane-covered ball for better spin on my wedges, but beginners often start with Surlyn balls for longer durability.

Table: Golf Ball Material Evolution from 1848 to Present

| Feature | Gutty Ball (1848–1900) | Rubber Core Ball (1900–1920) | Modern Golf Ball (1930s–Present) |

| Core Material | Solid gutta-percha (tree sap) | Solid rubber core with wound rubber threads | Rubber or resin core (multi-layered) |

| Cover Material | Gutta-percha | Gutta-percha | Surlyn (durable) or Urethane (high spin) |

| Construction | Molded by hand; hammered for texture | Machine-wound rubber layers + outer cover | Precision-molded layers with compression control |

| Flight Distance | 140–160 yards | 180–220 yards | 250+ yards (depending on swing speed and ball type) |

| Surface Texture | Initially smooth; hand-scuffed later | Uniform surface, some early dimple patterns | Advanced dimple patterns for lift and stability |

| Durability | Moderate (hardened sap, cracked over time) | Better durability, but still prone to scuffs | High durability (Surlyn) or soft, spin-friendly (Urethane) |

| Spin Control | Low spin, hard feel | Medium spin, better feel | Tuned spin levels by layer: low driver spin, high wedge spin |

| Manufacturing Process | Handmade, slow production | Semi-automated production with rubber winding | Fully automated, precision-based technology |

| Key Innovation | First mass-produced ball material | First rubber-core design; basis for modern balls | Layer control, compression tuning, aerodynamic consistency |

| Used By | Golfers worldwide after the featherie era | Professionals and the public by the 1920s | All players: from casual to PGA Tour pros |

Note: This table shows how each era brought new materials and technology to golf ball design, improving distance, spin, and control over time.

Golf Balls and Club Design: What Were the First Golf Balls Made of and How Did They Affect Golf Clubs

“As a pro who’s tested replica gear, I’ve learned something big: golf balls didn’t just change the game. They changed the clubs we used to.”

How Did Wooden Golf Balls Shape Early Golf Clubs

In the 1400s and 1500s, golf balls were made of hardwood, like beech or boxwood.

These wooden balls were heavy and didn’t compress much. Because of that, players used long-nosed wooden clubs with thick heads. These early clubs had to be strong enough to strike the solid ball without breaking.

I tried swinging a long-nose replica once; it’s much heavier than today’s drivers, and there’s barely any forgiveness. You needed serious strength and a steady hand.

Why Did Featherie Balls Lead to Thinner Wooden Clubfaces

When featherie balls came along in the 1600s, they were much lighter than wooden balls. Made of leather and goose feathers, they offered better flight but were also delicate.

That led to thinner, more refined wooden clubfaces, designed to strike the ball cleanly without splitting it.

In fact, when I tried hitting a featherie with a thick-headed club, it crushed the ball too much.

The ball shape and material forced clubmakers to improve precision and feel, setting the stage for the first real craftsmanship in golf gear.

How Did the Gutta-Percha Ball Lead to the Use of Iron Clubs

By 1848, the gutty ball, made from tree sap, was much tougher and more durable than featheries.

This allowed golfers to start using iron-headed clubs without worrying about damaging the ball.

For the first time, players could hit harder and shape their shots better with different club types, wood for distance, and iron for control.

I’ve used both replica irons and gutty balls in a demo round, and it’s wild how that one material change opened up an entirely new way to play.

FAQs

What Were Golf Balls Made from Originally?

The first golf balls were made from hardwood, like beech or boxwood, back in the 1400s.

Later came the featherie ball, made from leather and boiled goose feathers, and then the gutty ball, made from tree sap. These materials helped shape the way golf clubs and swings developed.

Are Any Old Golf Balls Worth Money Today?

Yes, some old golf balls are very valuable, especially featheries from the 1600s or gutty balls from the 1800s.

If they’re in good condition and come from a known maker, collectors may pay hundreds or even thousands of dollars. I once saw a feather in a Scottish museum valued at over $5,000.

What Kind of Golf Balls Did Tiger Woods Use?

Tiger Woods has used multiple models, but during his most famous years, he used the Nike Tour Accuracy and later the Bridgestone Tour B XS.

These are multi-layer urethane balls built for maximum spin, control, and distance, perfect for pro-level play.

Were Golf Balls Ever Smooth?

Yes. The first gutta-percha balls were smooth, but players noticed that scuffed balls flew farther.

That led to intentionally texturing and later dimpling the surface. Today, every golf ball has dimples to reduce drag and improve flight.

Do Old Golf Balls Still Work?

Old balls can still be hit, but they won’t perform like modern ones. A featherie or gutty might work for a few shots, but they’re better for display than distance. I’ve hit them in demos, they’re fun, but not for serious play.

Conclusion: From Wood to Urethane, The Evolution of Golf Ball Materials

“From handcrafted wood to high-tech cores, golf balls have always shaped how we play.”

Golf balls began with wood and leather, moved to gutta-percha sap, and now use urethane covers and rubber cores, like in the Titleist Pro V1.

Each material change improved distance, spin, and control, helping golf evolve into the game we know today.

To truly appreciate the sport, explore its history, hold a gutta-percha replica, or visit a golf museum. The past tells the story behind every shot we hit today.

The Beginnings of Golf – The First Golf Ball

Posts References:

The Complete History of the Golf Ball

History of Early Golf Balls